Capabilities

Fanuc C-800iB Wire EDM

X = 49.2″

Y = 38.3″

Z = 11.8″

________________________________________________________________________________________________________________________________

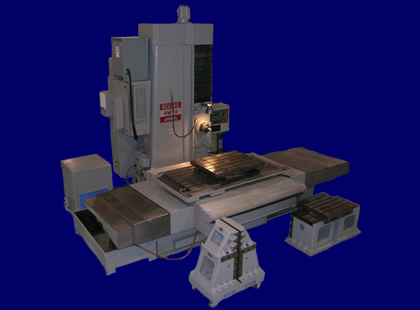

Devlieg 4W72 Horizontal Boring Mill

X = 72″

Y = 60″

Z = 20″ (Spindle Travel)

20HP on 4th Axis

Width = 16″ (Table Travel)

HAAS VF-8 Vertical CNC Mill

X = 64″

Y = 40″

Z = 30″

30HP on 4th Axis

Milltronics Partner VKM4 Vertical CNC Mill

X = 30″

Y = 15″

Z = 22″

5HP with 5″ Mill Slide

Bridgeport Torq-Cut 22 Vertical CNC Mill

X = 22″

Y = 16″

Z = 20″

10HP on 4th Axis

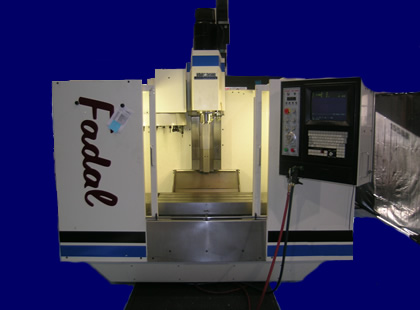

Fadal 5020 Vertical CNC Mill

X = 50″

Y = 20″

Z = 20″

25HP

HAAS TL-1 CNC Toolroom Lathe

X = 8″

Y = 30″ between centers

7.5HP

16″ Max Diameter

Fadal 3016 Vertical CNC Mill

X = 30″

Y = 16″

Z = 28″ (Spindle Travel)

15HP 5 Axis

Tooling Technologies Specializes in the Following Areas

- Marvel Band Saw

- Hitachi Vertical Mill

- Howa Sangyo Horizontal Mill

- Vertical Mills (4)

- Grob Vertical Band Saw

- Horizontal Cut Off Saw

- Okamoto 12″ x 24″ Surface Grinder

- Sunnen Hone

- TL-2 CNC Toolroom Lathe

- Drill Presses

- Shot Blaster & Vibratory Deburr

- Welder / Plasma Cutter

- Forklift – 5500 and 10000 lbs.

- Heat Treat Oven to Heat Treat Furnace

- 5 Ton Hydraulic Press

- Reid 6″ X 12″ Surface Grinder – With PG Optical Dresser

- Minster Press: 100 Ton, Bed Size 36″ X 48″ – Shut Height 21″ Max / 13″ Min, Stroke 8″

Whether it’s a high volume automatic automotive application or the development of a uniquely specialized process, TTI is willing and able to pursue any challenge.