Inspection / Reverse Engineering

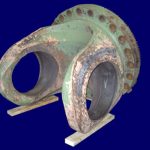

Through the use of our specialized measuring equipment listed below, Tooling Technologies offers a unique service to accurately create detailed three-dimensional drawings and models from digitized part data. The original part could be anything from an aircraft structural part to a production machine. Size can vary from as small as a dental pick to larger than a motorcycle die or a locomotive.

Additionally, all digitally extrapolated data can be applied to PC DIMS or any of our software packages, i.e., PRO E, Unigraphics, Solidworks, etc.

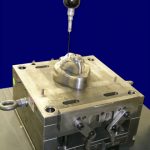

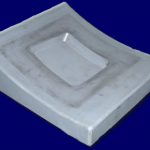

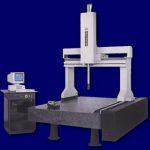

Brown & Shape Validator

X = 48″

Y = 72″

Z = 36″

4th Axis Indexing

*CMM Machines are calibrated annually to NIST

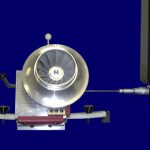

Brown & Shape Global Image

X = 27″

Y = 27″

Z = 27″

*CMM Machines are calibrated annually to NIST

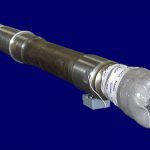

Leica AT401 3D Laser Tracker

Working Volume = 1050 Feet

Infinite Vertical Rotation = +/- 145 Degrees

Horizontal Rotation = 360 Degrees

ADM Accuracy = +/- .00039 Inch

*Laser Tracker calibrated annually to NIST

Brunson Optical Inspection

• Brunson optical jig transits, levels and scales with portable stands have standard measurement accuracies of .001 inch over seventeen feet.

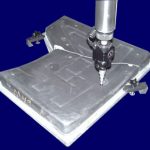

Romer Arm & Scanner

• Portable Romer Arm with 60″ measurement radius. The system also incorporates the latest in laser scanning technology.

Gage Laboratory

• 48″ x 72″ surface plate, height sets, comparator, ball bars, gage blocks, gage pins, etc.

• Rockwell Hardness Tester

• Surftest Profilometer

Whether it’s a high volume automatic automotive application or the development of a uniquely specialized process, TTI is willing and able to pursue any challenge.